Insulation

Types of Insulation

Blanket: Batts and Rolls

Blanket insulation — the most well-known and widely accessible kind of insulation — comes as batts or rolls. It consists of flexible fibers, most usually fiberglass. You can find batts and rolls produced using mineral (rock and slag) fleece, plastic fibers, and regular fibers, like cotton and sheep's wool.

ADVANTAGES OF BLANKET INSULATION

• Cost-Effective and Easy-to-Install

• Optional Facing Acts to Support Vapor Barrier

DISADVANTAGES OF BLANKET INSULATION

• Glass Fibers Can Irritate Lungs, Eyes and Skin, Which Can Cause Lung-Health Issues

• Performance Suffers With Poor Installation Technique (Rips, Tears and Open Spaces)

• Heat Conduction Possible Through Structural Elements

Concrete Block Insulation

The foundation and walls of a concrete home are typically made using a temporary structure. When picking insulated concrete forms, the framework remains set up, filling in as an extremely durable type of protection to commend the building process.

ADVANTAGES OF CONCRETE BLOCK INSULATION

- Benefit From the Strength of a Reinforced Concrete Wall

- Saves on Your Material Costs When Building Walls or Foundations

- Can Improve the Curing Time of the Concrete

- Less Setup Time to Schedule

DISADVANTAGES OF CONCRETE BLOCK INSULATION

- Don’t Work Well in Cold Climates

- Concrete Needs to Cure

- Cost Considerations

- Require a Bracing Process as Part of the Build

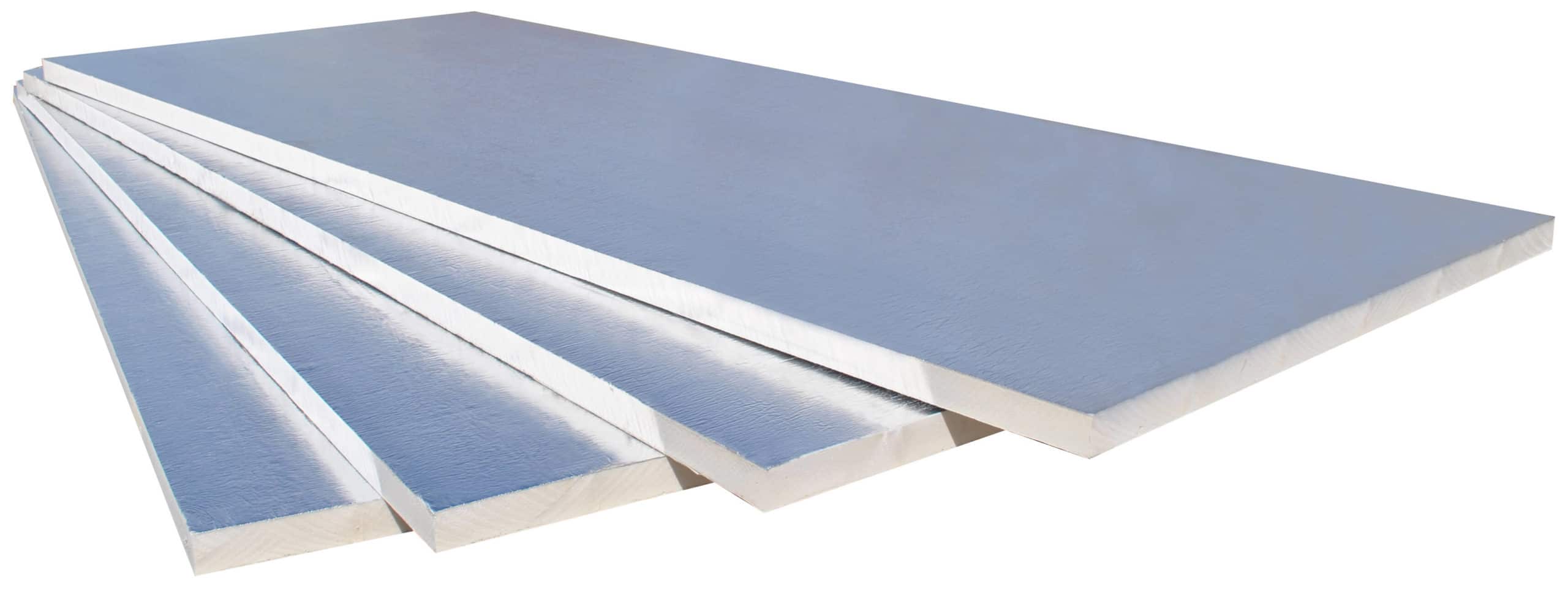

Foam Board or Rigid Foam

Rigid foam insulation, additionally called foam board or board-stock, is produced using foam plastics and is a popular choice for insulating foundations and building exteriors. It tends to be utilized inside wall cavities also. It is sold in rigid board-style sheets of varying sizes. Rigid foam can be provided with a foil facing to additionally further develop its insulating characteristics.

ADVANTAGES OF RIGID FOAM INSULATION

- Offers Very High R-Values Compared to Loose-Fill Insulation

- Water Resistant

DISADVANTAGES OF RIGID FOAM INSULATION

- Must be Tightly Fitted to Stop Air Infiltration

- Joints Between Sheets and Boards Must Be Taped to Prevent Air Flow

- Susceptible to Sunlight

Insulating Concrete Forms (ICFs)

Insulating concrete forms (ICFs) bring about cast set up concrete walls that are sandwiched between two layers of insulation material. These systems are solid and energy efficient. Common applications for this technique of development are low-rise structures, with property uses going from residential to commercial to industrial. Customary completions are applied to interior and exterior faces, so the buildings seem to look similar to typical construction, although the walls are typically thicker.

ADVANTAGES OF ICF'S

- Improves the Structure Strength of the Final Product

- Uses Less Concrete Than Traditional Methods to Complete a Project

- Can Save You a Lot of Time When Building Structures

- Can Still Install Your Plumbing and Wiring

- Uses Steel Rebar to Reinforce the Structure

DISADVANTAGES OF ICF'S

- Works Best in Hot Climates

- Can Still Release the Structure Too Early

- Cost of an ICF Wall is an Issue to Consider

- Will Need to Deal With the Common Seam in the Wall

- There is a Bracing Process You Must Follow to Keep the Walls Straight

Blown-In Insulation

Unlike insulation batts, rigid foam boards or plastic wraps, blown-in insulation is a loose, airy material that, as the name suggests, is blown by a machine into uninsulated areas of the home. You can add blown-in insulation during development, or to retrofit a current home, even inside completed walls. R-Value, or thermal resistance value, is the deliberate capacity of insulation to retard instead of transmitting heat. The higher the R-value, the more powerful the insulation.

ADVANTAGES OF BLOWN-IN INSULATION

- Insulation Efficiently Fills Gaps

- Materials Can Be Layered For Added Protection

- Blown-in Insulation Flows Down Around Wall Studs

- Blown-in Fiberglass is Considered Flame Resistant

- Most Blown-in Cellulose Materials are Non-Toxic

DISADVANTAGES OF BLOWN-IN INSULATION

- Requires Professional Installation

- Can be Very Messy

- The Weight of Blown-in Cellulose Can Cause Ceiling Sag

- Damp Blown-in Insulation Can Promote Fungal Growth

- Material Becomes Very Problematic When Wet

Reflective System

Reflective insulation (otherwise called foil insulation) is generally produced using aluminum foil or aluminized polyester. Reflective insulation is normally utilized in two primary regions. The first is in unventilated cavity walls; the second is as insulation in pitched or angled rooftops.

ADVANTAGES OF REFLECTIVE INSULATION

- Very Effective in Warm Climates Where it is Useful in Keeping Buildings Cool

- Does Not Degrade Over Time

- Thin and Fairly Lightweight

- Can Be Used as a Vapor Barrier

- Relatively Waterproof and Unaffected By Moisture

- Non-Toxic and Non-Carcinogenic - Safer and Easy to Install

DISADVANTAGES OF REFLECTIVE INSULATION

- Generally More Expensive

- Requires Being Combined With Other Forms of Insulation in Colder Climates

- Potential of Becoming an Electrical Hazard

- Relies on Being Clean and Free of Dust and Debris

Fiberglass Insulation

Fiberglass insulation is the most well known insulation available today. It is sold in two forms: blankets (either long rolls or batts) and loose fill. The previous accompanies paper backing, for installation between the studs in walls and the joists in floors, or with no backing, for use in ceilings. The latter is for the most part utilized in ceilings, however it can likewise be blown into wall cavities.

ADVANTAGES OF FIBERGLASS INSULATION

- Inexpensive and Effective

- Does Not Shrink

- Does Not Burn

- Some Fiberglass Insulation Uses Recycled Glass, Reducing its Ecological Footprint

DISADVANTAGES OF FIBERGLASS INSULATION

- Protective Gear Must Be Worn When Installing Fiberglass Insulation: The Tiny Slivers Will Lodge in Skin and are Small Enough to Be Inhaled

- Requires a Vapor Barrier to Protect it From Moisture

- Fiberglass Blankets Do Not Seal Wall and Ceiling Spaces Very Tightly

- Inhaled Slivers of Fiberglass Irritate the Alveoli and Can Cause Lung Disease

Sprayed Foam Insulation

Spray Foam Insulation is a product which has been accessible to homeowners beginning around 1986. Numerous new development projects utilize this item since it offers comfort and energy efficiency benefits. It can assist with fixing issues with inadequate insulation, lessen utility costs, and retrofit unfinished crawl spaces or attics with a useful product that assists a house with feeling more like a home.

ADVANTAGES OF SPRAY FOAM INSULATION

- Can Provide a Powerful Level of Support to Homeowners

- Can Reduce the Utility Bills for Homeowners

- Provides an Airtight Seal That is Difficult to Break

- Impermeable to Water

- Ensure Current Licensing For Installer

DISADVANTAGES OF SPRAY FOAM INSULATION

- Does Not Always Fill Every Possible Cavity

- Might Encourage Water Damage for Some Homeowners

- Can Sometimes Shrink

- Requires a lot of Experience to Get It Right

- Installations May Not Meet Necessary R-value Code Requirements

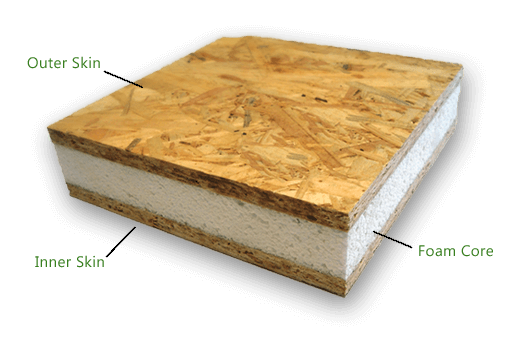

Structural Insulated Panels (SIPs)

Structural Insulated Panels are rigid panels of foam or polystyrene insulation, that have been sandwiched between Oriented Strand Board (OSB). They come as pre-assembled sheets that can basically be slotted together, to create the whole structure of your new home.

ADVANTAGES OF STRUCTURAL INSULATED PANELS

- Very Strong

- Flexible

- Less Costly, and Takes Less Time

- Made From Foam and are Not Prone to Infestation From Pests

DISADVANTAGES OF STRUCTURAL INSULATED PANELS

- Not Much Room for Changes to Be Made

- If Your SIP Becomes Wet, They Will Start to Degrade Very Quickly

- The Outer Wood Can Rot, Causing the Composition to De-laminate

10 Big Warning Signs of Insulation Issues

1. Your Walls are Freezing

2. Holes in the Exterior Walls

3. Bugs or Mice

4. Moisture/Internal Condensation

5. Mould

6. Drafts

7. Cold Rooms

8. Ice Dams

9. Old Insulation

10. Sky High Energy Bills

Find Local Contractors That Specialize in Insulations!

Armour Shield Coatings Inc

Haliburton, ON K0M 1S0

(705) 457-6915

Emmerson Lumber Limited

63 Maple Ave, Haliburton, ON K0M 1S0

(705) 457-1550